Paws Pumps has a rental fleet of 20,000 pipe slings that they not only have to manage in terms of inventory, but also manage inspection/recertifications. RFID offers significant improvement in process for managing both.

The company also manages other companies sling inventory. RFID allows them to streamline this service business with improved inspection scheduling, automatic emails, and other labor saving solutions. This level of service is a big selling point with new customers and will generate significant new revenues for the company in 2010. This outside the box solution has also got the company thinking about customers outside of their traditional pool of oilfield customers.

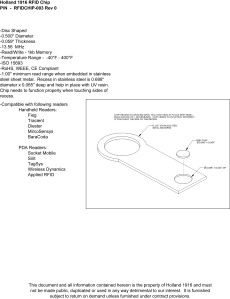

The durable metal RFID tagging solution used by Paws Pumps comes from Holland 1916 Inc. a full service product identification company located in North Kansas City MO.

This RFID Tag was burned in the field during actual use. Even after sustaining fire damage, the tag was readable. Now, that is a durable design.

This RFID Tag was burned in the field during actual use. Even after sustaining fire damage, the tag was readable. Now, that is a durable design.